Specifications

Standard lead length is 6 inches. For custom lengths, please contact the factory at sales@rdfcorp.com.

| Thermocouple Type & Lead Material |

Type K - Chromel/Alumel | Type E - Chromel/Constantan | Type T - Copper/Constantan |

|---|---|---|---|

| Foil Thickness | 0.0005" 12.7 µm |

0.0005" 12.7 µm |

0.0005" 12.7 µm |

| Lead Dimensions | 0.002" x 0.03" 50.8 µm x 76.2 µm |

0.002" x 0.03" 50.8 µm x 76.2 µm |

0.002" x 0.03" 50.8 µm x 76.2 µm |

| Temperature Range | -320 to 1500°F -195.56 to 815.56°C |

-320 to 1200°F -195.56 to 648.89°C |

-320 to 700°F -195.56 to 371.11°C |

Features

Ideal Thermal Contact, Fast Response

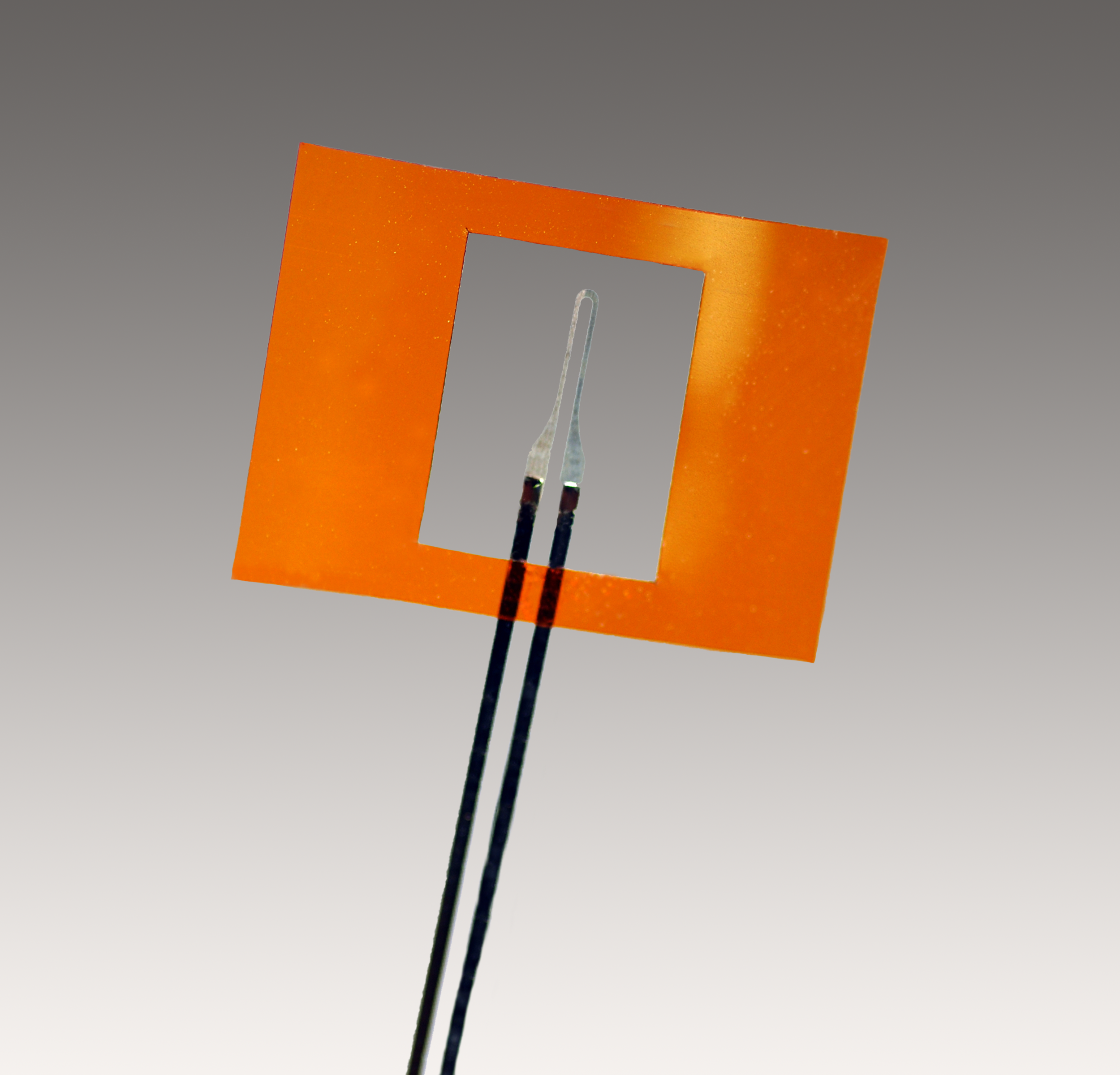

Thin foil thermocouples, with butt bonded junctions, provide accurate, fast response sensors for surface temperature measurements. They are available in a free filament style with removable carrier and in a thin, high temperature laminate style with the sensor embedded in paper-thin laminate.

Thin foil gives extremely low thermal inertia plus maximum thermal coupling to the mounting surface. Thermocouple grade materials are used throughout the foil and leads for accuracy. Errors caused by thermal conduction between junction and leads are negligible, since the length to thickness ratio of the foil junction portion ranges from 500:1 to 2000:1.

Micro-Foil® butt bonding produces thermocouples with no increase in thickness or mass at the junction. Location of the junction is definite and concise, essentially a short line, not spread out. Butt bonded foil is an intimate thermal layer at the sensing surface.

For handling ease, a temporary carrier of polyimide film supports the bare foil. The Kapton® polyimide film is tough, flexible, and dimensionally stable. It is exceptionally heat resistant and inert. Portions of the carrier can be easily cut away with a scissors or knife.

The foil sensor is fastened to the polyimide film carrier, at one point only, by a thermoplastic adhesive. During installation, the carrier is normally removed. However, all or part of the polyimide carrier, due to its heat resistance and inertness, may be left in the sensor installation with little or no loss in thermocouple performance. The carrier will withstand the prolonged heating at 600° to 750°F required for the curing of most ceramic cements.

RdF bare foil surface thermocouples work well with ceramic cements at high temperatures. The free foil thermocouple can be easily brushed into a thin second layer of cement, following application and drying of a thin insulating layer, to produce an ungrounded junction. To remove the carrier film during installation, peel back carefully or touch the attachment point with a hot soldering iron. Installation can be made directly to nonconductive materials with any of a variety of cements. Grounded junction may be made on conductive materials if desired. Grounded junctions have response times between 1 and 5 milliseconds.